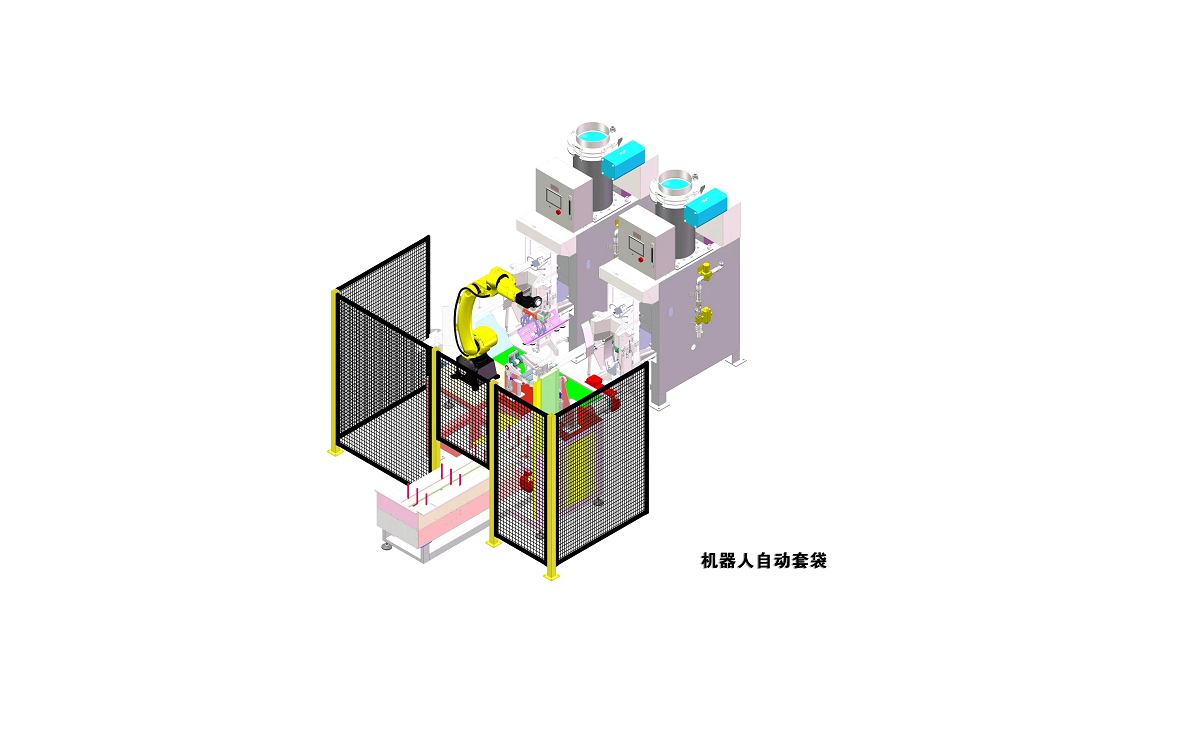

Model:Automatic bagging machine

The task of the automatic bag loading machine is to automatically place the open bag at the bag clamping position at the discharge port of the packaging machine. The wide application of AWE automatic

The task of the automatic bag loading machine is to automatically place the open bag at the bag clamping position at the discharge port of the packaging machine. The wide application of AWE automatic bagging machine in bulk material packaging enables it to meet the different needs of customers in industrial packaging technology and equipment. With reliable and simple installation means, our automatic bagging machine is designed to meet the growing customer demand with maximum efficiency and flexibility.

When AWE automatic bagging machine works, it first sucks up the bag, opens the bag mouth and sends it to the discharge port of the packaging machine to fill the empty bag, and then sends the filled bag to the sealing equipment, which is widely used in building materials, chemical, feed, grain and other industries. It is usually packed in 10kg~50kg bags, with a maximum of 1200 bags/hour.

Main features:

1. The automatic bag feeding device is suitable for high-speed continuous operation.

2. Each execution unit is equipped with control and safety devices to realize automatic and continuous operation.

3. The servo motor drive device can play a higher role.

4. Filling method: 1 round/1 bag

5. Packaging material: particles/powder

6. Bag size: maximum length 1000mm, maximum width 600mm

7. Sealing method: heat sealing/sewing/hot melt tape/wrinkle belt

8. Easy to clean, suitable for conversion of different specifications of packaging bags.

9. High precision filling and weighing, reliable results.

10. The application of general and industrial components extends the service life of the machine and adopts the best mechanical production mode.

11. Manufactured according to Australian and international standards.

12. The pneumatic and electrical control elements are installed in the positive pressure closed box to ensure the dust-free environment of the components.

13. The control system is based on the most advanced PLC control interface to ensure broadband data transmission. This interface is easy to operate, and the operator can easily master all operations.

14. Simple operation. The control panel can ensure the operator to stop, run, retract and release the bag clamp, clamp timer, step input, emergency stop and other operations.

15. This automatic bagging machine can be upgraded to a fully automatic bagging and stacking system